FEATURED STRUCTURAL PROJECT

OROVILLE DAM

Lake Oroville and Oroville Dam, located in the Northern California town of Oroville, are part of a complex which includes Hyatt Powerplant, Thermalito Diversion Dam and Powerplant, the Feather River Fish Hatchery, Thermalito Power Canal, Thermalito Forebay, Thermalito Pumping- Generating Plant, and Thermalito Afterbay.

The Oroville- Thermalito Complex was designed as an efficient water and power system. It stores about 3.5 million acre-feet and generates power from releases made through Hyatt Powerplant and two other Thermalito generating plants.

At 770 ft. underground, Oroville Dam is the tallest dam in the nation.

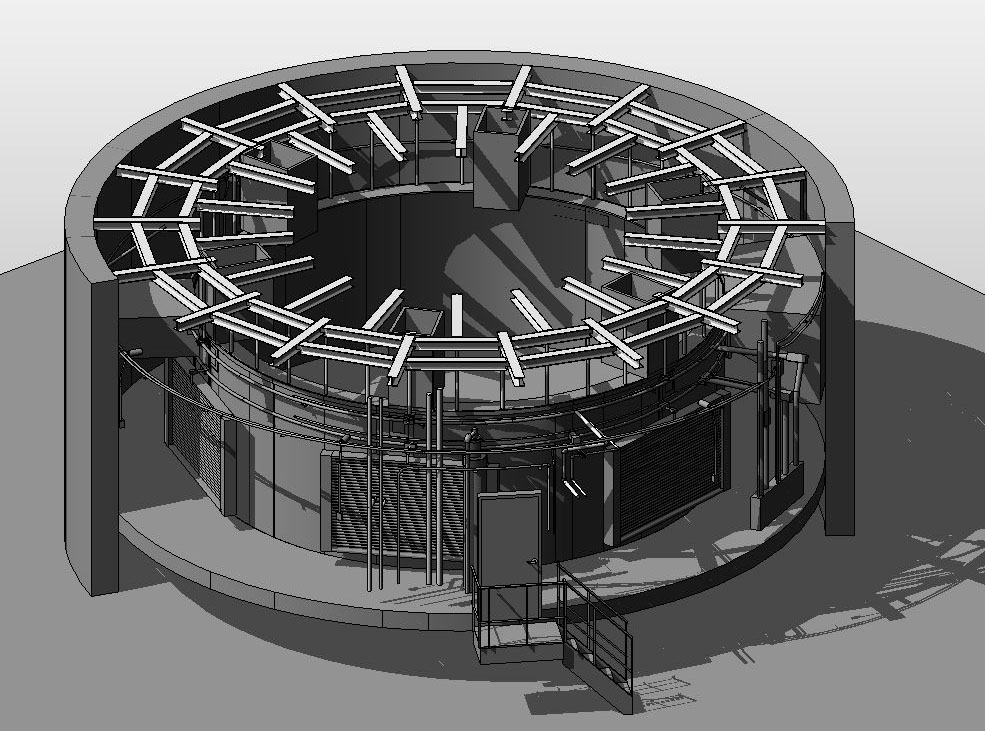

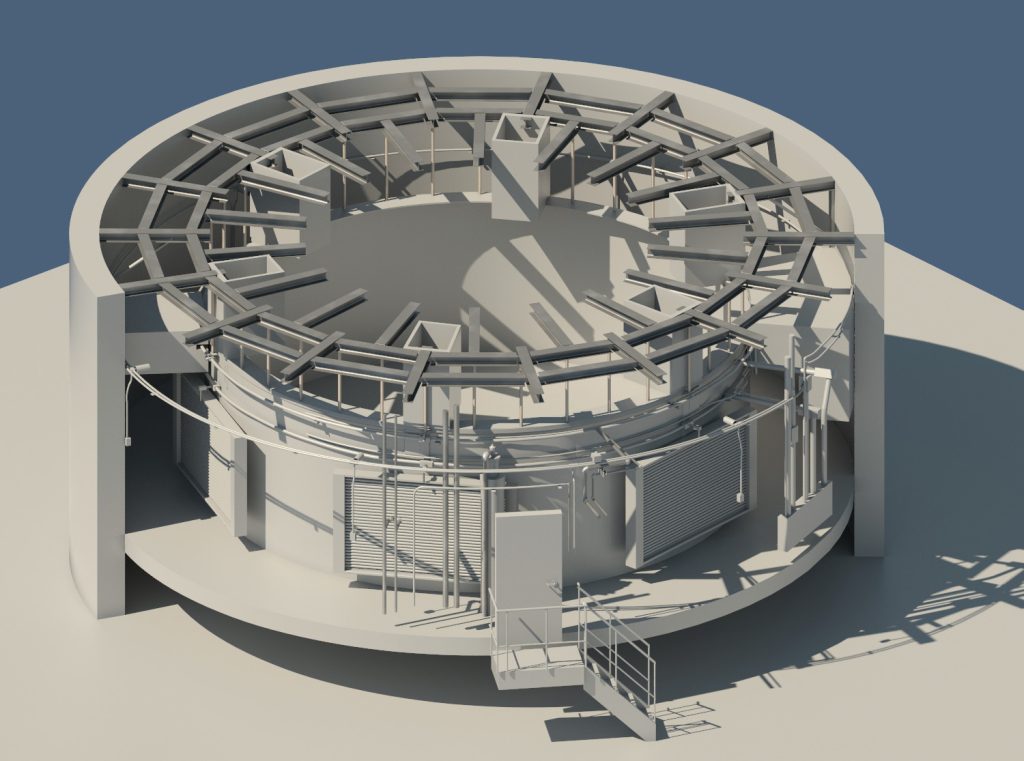

Design Challenge:

- Design an aluminum steel catwalk within the walls of the 40 ft. diameter turbine.

- Catwalk to be pre-manufactured off-site and intstalled on-site.

- Catwalk pieces not to exceed 40 lbs. each.

- Catwalk must be removable.

- Catwalk design elements must be designed so as to avoid existing piping around turbine walls.

- Document existing conditions and create a 3D model for the creation of shop drawings, manufacture templates, and installation visual guideline.

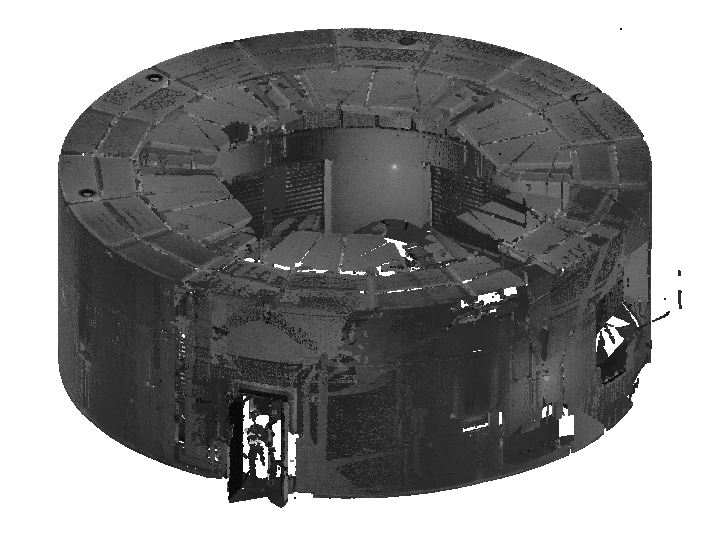

3DVDT scanned two of the six power generator housing units and created a 3D model. Each generator has a 40 ft. diameter outer wall, with a 34 ft. diameter housing unit inside. We scanned the 6 ft. area between the wall and housing for the purpose of engineering a catwalk to be designed and manufactured off site and installed piece by piece on site. Accuracy was critical, as the catwalk was to be designed around the existing piping. This process using traditional methods would have been much less accurate and more time consuming, thus much more costly.

After the reality capture process, a 3D model was created directly from the scan data (point cloud). The proposed catwalk design spans from the top of the inside drum to the outer concrete wall. Some of the existing pipes/elements lower than 4 ft. from the top of the drum were not obstructions and therefore not necessary to model.

Scan to BIM is highly beneficial in MEP projects as it allows for the accurate conversion of physical building data into digital models, enabling precise coordination, clash detection, and streamlined design and installation processes for mechanical, electrical, and plumbing systems.

Contact us now to talk about your MEP project and how we can help.