Project Success:

Documenting difficult-to-access existing conditions with the use of 3D laser scanning technology

Case Study Learning Objectives:

- Describe access challenges and create planning strategies to develop methodologies for capturing and documenting difficult to access sites.

- Illustrate the advantages of using laser scanning technology for precise measurement of difficult to access site and/or existing conditions.

- Define appropriate procedures needed for access, safety, successful data capture and point cloud registration for creating accurate as-built documentation.

- Explain the multiple deliverable benefits produced from the data captured by the 3D laser scanner for project stakehold

Project Description

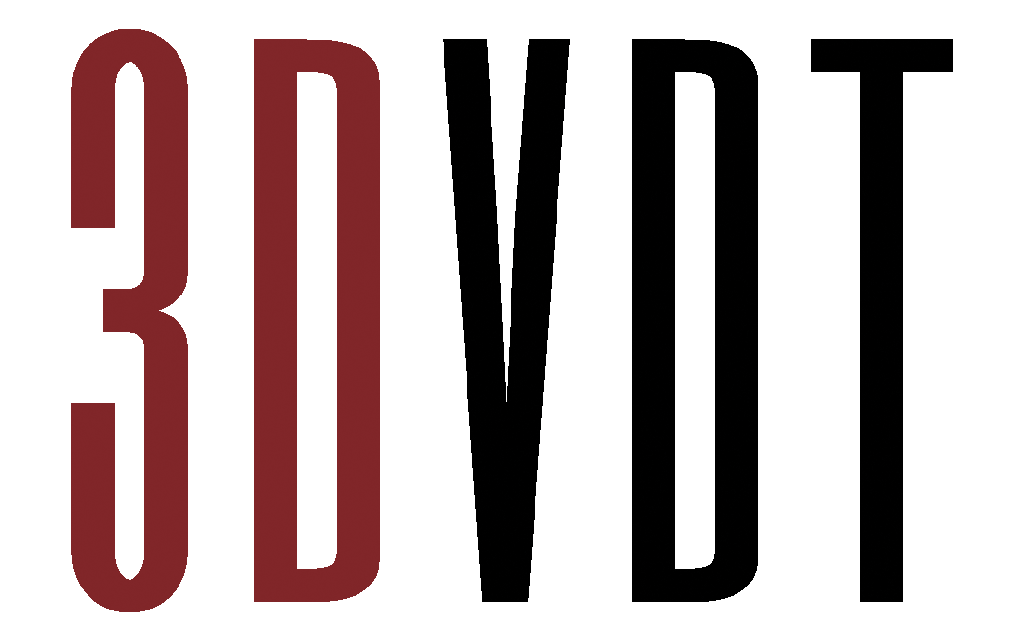

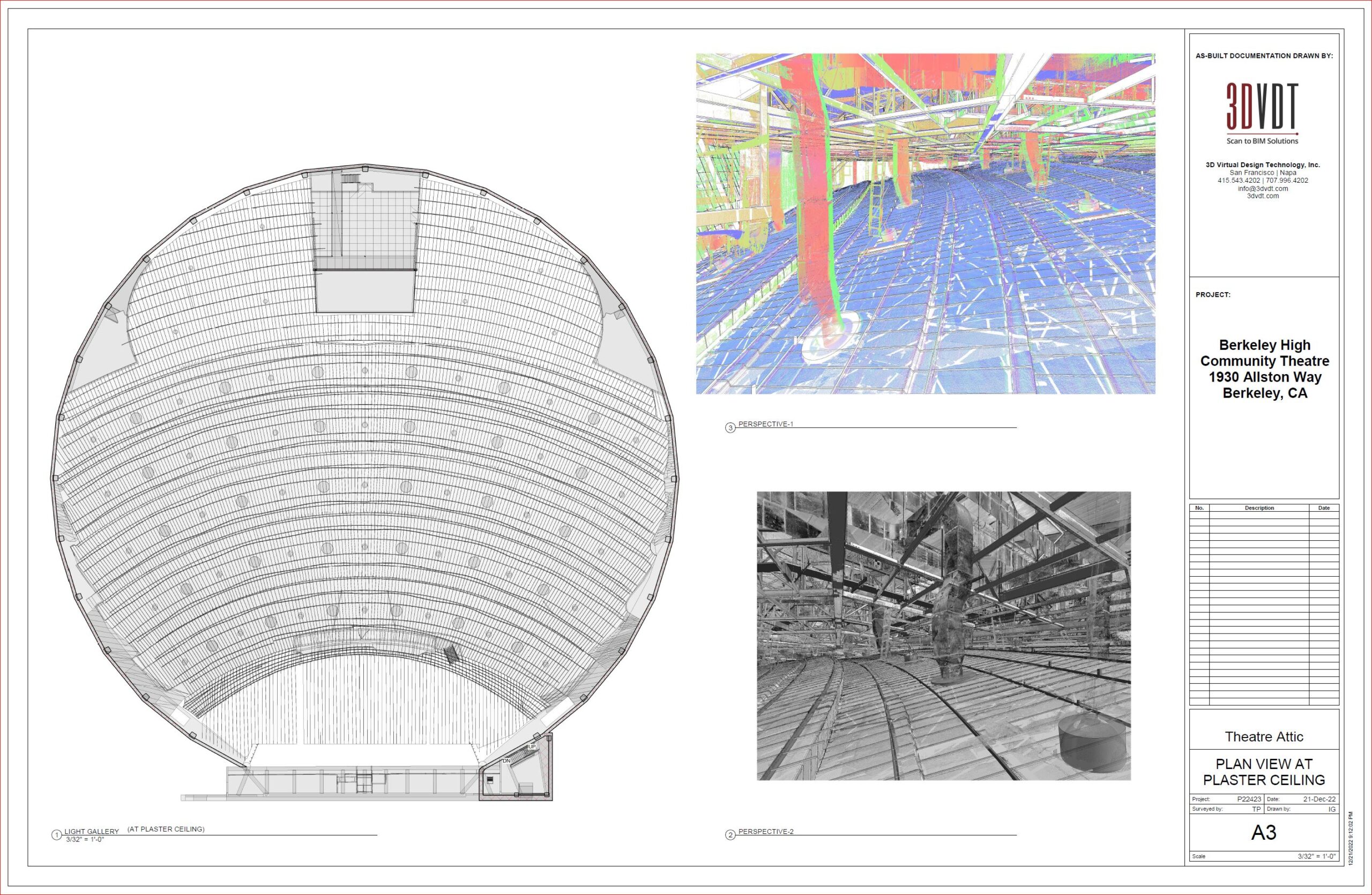

Located in Berkeley, California, the 1950’s, 3500-seat Berkeley Community Theatre (Henry H. Gutterson and William Corlett, Sr., Architects) is designated a local landmark and contributor to two historic districts for its Art Deco style. The historic theatre has been under construction for nearly four years, undergoing a comprehensive renovation and seismic retrofit by CAW Architects, and is slated to open in January 2024.

Precise documentation of the existing conditions was crucial to the designing, planning, construction, and installation processes for structural reinforcement of the plaster ceiling. However, the difficult to access site presented several challenges.

Overcoming Access Challenges with Laser Scanning Technology

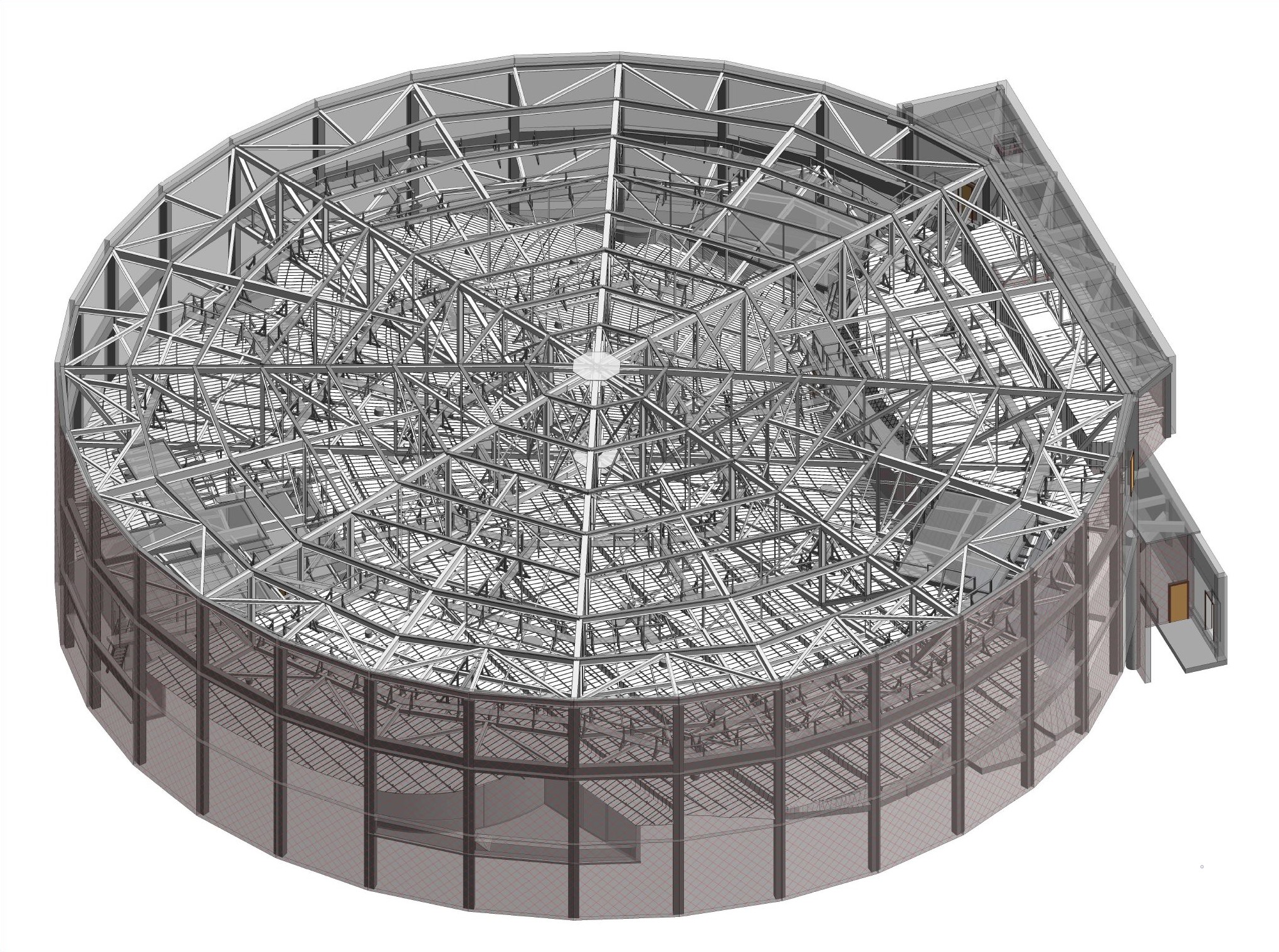

It was critical to capture plaster ceiling of the theatre, yet it was extremely difficult to access. In the attic space approximately 65 feet above the auditorium floor, the plaster ceiling lies beneath the structural steel framing and MEP densely interspersed at various elevations and angles throughout the 80-foot diameter rotunda. The curved, tiered ceiling slopes downwards of 28 feet and is visible from an 18-inch-wide wooden catwalk system intricately woven throughout the congested space. From the catwalk, wooden ladders descend to access each of the 43 recessed ceiling light fixtures, with a 10-inch wooden plank that is supported only by the steel ceiling grid to stand on.

Due to the instability and unsafe access to the plaster ceiling, 3D laser scanning was the ideal tool for capturing the ceiling surface area, steel grid framing and support hangers from a distance, with millimeter accuracy (Fig.1).

Careful Planning & Execution for Precise Measurement

To ensure successful registration of the individual scans, 3-dimensional spheres and 2D checkerboard targets were placed strategically throughout the space (Fig.2). Scanning at a 6mm resolution and collecting over a million points per second, the scanner was placed at 5-foot intervals along the catwalk to ensure optimal line-of-site visibility and sufficient point overlap of the ceiling surface and supporting elements.

While the plaster ceiling was the main area of focus, the scanner automatically captured the architectural, structural and MEP elements of the entire attic space, providing the design team with the ability to navigate throughout the site virtually from a program viewer. With one day site preparation and three days to scan, 3D laser scanning proved to be a fast, safe, and efficient method to accurately field measure the difficult-to-access site and existing conditions, and ensured the successful delivery of precise 3D and 2D as-built documentation (Fig.3).

At 3DVDT, we providing expert 3D capture services to help AEC professionals harness the full power of 3D as-built documentation. To discover how our services can transform your next project, get in touch with us today by filling out a contact form or emailing us.